This page describes the JBM Industries flange type carburetors socket boot carburetor holders for intakes on Rotax 912 and HKS engines. JBM is selling exactly the same part for both of these engines. These sockets fit BING model 64 CV carburetors used on Light Sport Aircraft. This part matches the original Rotax part of the latest type and is made of 80 durometer TSR material. (Same hardness as Rotax part)

75mm between bolt hole centers.(3 inches)

29mm high, and a 38mm minimum diameter throat

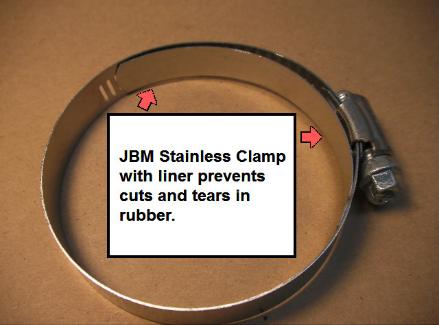

Worm Clamps for our Aircraft and Motorcycle Carburetor Sockets. Working range 1 13/16" to 2 3/4". These have special liner tail for soft rubber installation.

There have been various attempts to make the rubber sockets stronger and solve cutting and tearing problems. To prevent cutting of the rubber by the clamp, Rotax now supplies a "limiter" on every clamp to prevent "over tightening" of the clamps. The problem with this is that: sometimes the clamps are not tight enough, and the carburetor spigot can move and "work" inside the socket. This causes the locking rib and inside of the socket to get chewed up and torn. Sometimes the carburetor can "pop" off, usually on start-up. JBM recommends that limiters be removed when using the JBM sockets to be sure the carb is tight and cannot move in the sockets. WARNING: Never over-tighten sockets.

HKS engines shake a lot and have all sorts of installations with very poor brackets to support all the weight on these carbs. Some things can help, such as plates to interconnect the carburetors or springs to help support weight. Another solution we have seen on Rotax 912 engines is "coil springs" to hold the carbs on. They have also tried to add an aluminum ring internally to prevent rubber damage inside. Do NOT use ring with JBM parts.

These various attempts to solve a problem are only working on the symptoms, and not curing the real problem. Be sure you have good motor mounts to prevent engine shaking, and take the time to add the supports and brackets to take the weight of air boxes, tubes, air filters, etc.

Please keep in mind some owners make horrible installations on their flange sockets and carburetors

Engines sometimes shake way too much, and can rip a perfectly good rubber flange in two.

Here we see various examples of rubber torn from the metal plate.

Above we see an example of poor vulcanization after only 50 hours. The rubber was not properly vulcanized to the metal, and this allows corrosion in.

A very hot humid environment seems to make this worse. These photos were sent to JBM Industries by various new customers as the reason they want to buy JBM flange sockets.

Above we see another solution to improper mounting of the carbs and air filters. This is a bracket that is made to go under the clamp and attach's to the bolt heads. This is an attempt at a solution to prevent tearing of the rubber socket that is too soft and weak for all the weight of the intake tubes, air filters, etc. You will also notice springs that have been used to help support the carburetor's weight.

Another look at that bracket.