Easy way to remove stuck slides is to heat the carburetor housing under a lamp as shown here. When warm, a small amount of twisting will remove almost every slide. Never use a hammer or tool to force the slide as they are delicate. Heat softens the years of varnish deposits. Varnish is clear and can invisibly block jets. Use a chemical dip cleaner to clean carburetor metal parts. Never put plastic or rubber parts in the chemical dip. A layer of water on top of the chemical prevents evaporation, so get parts in deep. Never use compressed air without removing float bowls as it can collapse metal floats from pressure.

Heat carb under incadesent lamp.

Use a chemical dip cleaner to clean carburetor metal parts.

Here we see the restoration of an early Honda 350 carburetor slide that was damaged.

After removal of the old diaphragm and metal and plastic rings, an aluminum collet was made for the lathe to just fit the slide. The broken part of the slide was then machined away.

A new thin "sleeve" was made and fastened with Loc-Tite into the slide. Warming the slide expands it and makes the Loc-Tite cure fast.

As you can see this made a suitable repair that can be done by anyone having a metal lathe. Another vintage bike back on the road.

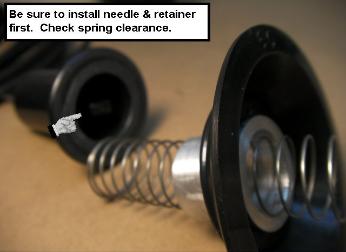

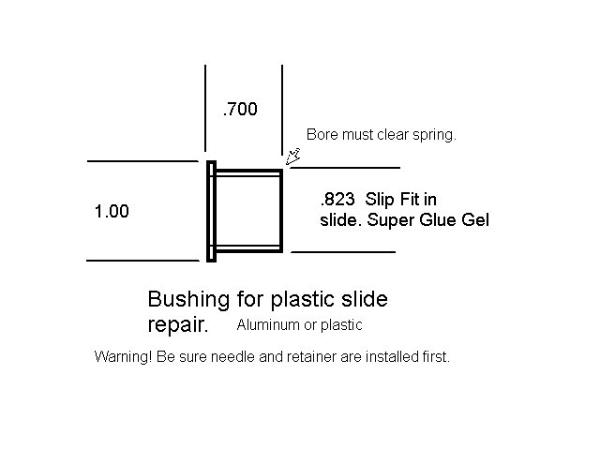

Removal of old diaphragm from plastic slide is difficult as the plastic retaining ring is glued very well to the slide. The plastic slide is brittle and edge can crack away as shown above. Repair requires removal of retainer and needle, cleaning of slide, and a slip fit bushing made from aluminum or plastic that is glued into place after needle and retainer are installed.